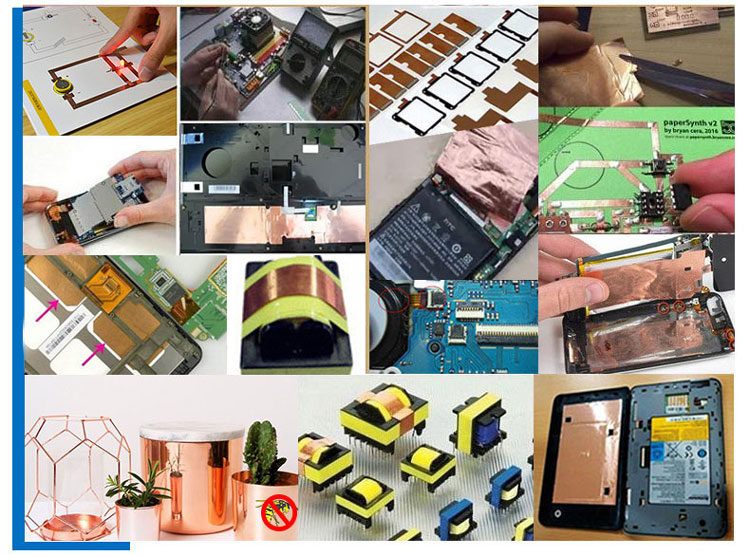

See This Report about Copper Foil

Wiki Article

Rumored Buzz on Copper Foil

Table of ContentsThe Ultimate Guide To Copper FoilCopper Foil - An OverviewThe Definitive Guide for Copper FoilWhat Does Copper Foil Do?The Only Guide for Copper FoilAn Unbiased View of Copper FoilGet This Report on Copper FoilSome Known Details About Copper Foil Rumored Buzz on Copper Foil

When you copper aluminum foil stained glass lots of inquiries turn up that you weren't taught exactly how to take care of. Queries such as these: What dimension aluminum foil do I need? Just how do I save stained glass foil? Where do I begin foiling on a piece? Scroll down to locate an entire listing of solution to assist improve your discolored glass copper hindering.If you intend for the copper foil you'll be spot on. 3/16" 1/4" aluminum foil works well for most standard copper foil stained glass pieces.

All About Copper Foil

Some Known Incorrect Statements About Copper Foil

The rolls fit flawlessly as well as when the cover is protected in area, it assists preserve the foil. Start hindering away from the perimeter of an item When you copper aluminum foil discolored glass it's finest to start foiling away from the outside edge as this makes for stronger attachment. This is because the foil isn't signed up with outside edge where is is more probable ahead loose.

Do you know just how to copper foil discolored glass that is greatly textured? If you have actually tried this you'll understand that the aluminum foil breaks as you attempt to go from high to low. Despite shallow distinctive glass (ripples) the foil often damages as it goes across the ripples instead of well contouring to it.

Our Copper Foil Diaries

Use a cork for kinking textured glass as it is softer and also gives stress while decreasing tearing. It cleans the aluminum foil also!Much better still, you can use a to eliminate the hefty texture on the glass prior to hindering. Use lined paper to assist centre the copper aluminum foil When you copper aluminum foil tarnished glass by hand it can be difficult to centre the foil.

6 Easy Facts About Copper Foil Shown

Usage lined paper as a guide! When you copper aluminum foil stained glass you do not have to have a harsh surface for the aluminum foil to stick to.Your glossy cut edges are great without grinding. Just take care of your fingers. You can just numb the sharp edges off with a damp scythe stone to avoid reducing on your own and to protect against sharp edges cutting the aluminum foil. Ground sides require to be thoroughly cleaned up prior to foiling. Occasionally when you copper foil tarnished glass the aluminum foil comes away check from the edge.

Copper Foil Can Be Fun For Anyone

If you solder too slowly or go over the solder repetitively the aluminum foil adhesive melts as well as comes to be unstuck. It's worth remembering that the glue is there to hold the foil in place until it's soldered.

If you tin the edges rather than creating a beaded side. "Tinning" indicates covering them with a thin finish of solder. "Beading" is a spherical side of solder that 'clings' to the edge of the discolored glass as well as is a lot stronger. I have a video on published here how to do a handmade side on this page. Be gentle when cleansing and also sprucing up.

More About Copper Foil

There are extra responses concerning copper aluminum foil not sticking here.Wiring demand is among one of the most vital motorists for electronic bundle selection. The Semiconductor Market Association (SIA) (Sematech) releases a document often to recommend the industry of today as well as future circuitry need for a range of product types. Table 1 reveals components of the table that was published in 1999 (copper foil).

The Best Strategy To Use For Copper Foil

Lower I/O remain in hand held items that endanger on efficiency to attain their smaller sized dimension. These I/O values are leading edge applications with the largest number of I/Os. Normal applications have much reduced demand but in time will capture up to the cutting edge needs, investigate this site which are 510 years ahead of the typical product.This only occurs in limited layouts. The other piece of the I/O equation is the size of the chip. This is mainly a feature of exactly how lots of circuits are being made use of by the application. In Table 2, SIA (Sematech 1999) has actually specified chip dimension as a feature of the type of application. copper foil.

The Only Guide to Copper Foil

In this technique, a gold or aluminum wire is adhered to a pad on the chip as well as then knotted to a pad on the chip service provider, which is the base for the component. A regular chip to substrate connection making use of cable bond is kept in mind in Fig. 1. With discrete cords, their placement can not be also close or the cables will certainly touch each various other.Report this wiki page