Examine This Report on Plastic Extrusion Companies

Wiki Article

Getting My Custom Plastic Extrusion Manufacturers To Work

Table of ContentsPlastic Extrusion Manufacturers for BeginnersIndicators on Custom Extrusion Manufacturer You Need To KnowFascination About Plastic Extrusion CompaniesThe Ultimate Guide To Extruded Plastic Profiles5 Easy Facts About Plastic Extrusion Profiles Explained

We can also offer custom-made laminations and also would certainly more than happy to send you examples upon request. We currently have 7 lamination stations that can deal with various kinds of custom plastic extrusions. We offer custom-made packaging and are presently packaging an extruded account product that is sold to a "Big Box" Business.Be it straightforward, intricate, hollow, coextruded, or embossed, our group of experts can tailor it for you. On top of that, our specialists recognize that no two jobs coincide as well as we plan to keep it in this way. This suggests that here at Keller Products we can provide you any variety of products for your style requires.

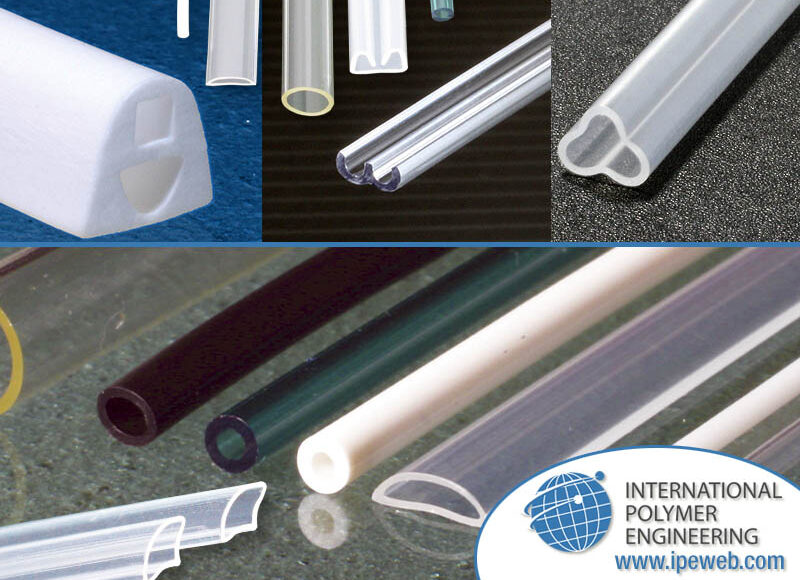

Custom-made extrusions are tailor-made items that are produced forcibly resources with a die or mold. This procedure is referred to as extrusion. Extrusion is used to develop objects of a taken care of cross-sectional profile, such as pipelines, tubing, and also rods. The raw product, referred to as the "extrudate", is initial softened by home heating.

The form of the die or mold and mildew identifies the last form of the extrudate. Extrusion can be used to produce products from a range of products, including steels, plastics, and compounds. Common applications for this process consist of vehicle components, electric channel, as well as weatherstripping. It is used in a selection of industries, consisting of vehicle, construction, as well as production.

Everything about Custom Plastic Extrusion Manufacturers

These companies can aid you to make the excellent product for your demands as well as after that produce it making use of the extrusion process. Prototyping your following important job can be as easy as speaking to Alpha Custom-made Extrusions, Inc.In enhancement, Alpha Custom-made Extrusions, Inc. supplies a host of secondary capacities to finish your total project.

Consist of hinges, seals, top coats, numerous shades as well as various other features

Plastic Extrusion Manufacturers for Beginners

Preparations differ based upon our Finite Ahead scheduling system. Our invoice of your order starts the scheduling procedure. Is all tooling produced in-house? Yes, all tooling is made as well as made by Sandee. What is the common lead time for a production order? The characteristics of customized production typically cause quick changes to tooling, manufacturing and fabrication schedules.

We can generate an extra accurate quote if we can reference a Pantone color number. If no Pantone number is readily available, anything can be customized shade matched. The length of time does a custom shade match take? It typically takes ten working days to obtain a color chip to you for authorization, and ten extra functioning days to produce the custom shade concentrate from the approved color chip.

They are noted in order of choice. DWG Auto, CAD 2000 DWG Any revision of Auto, CAD DXF Auto, CAD 2000 DXF Any revision of Car, CAD Please call if you can not send the documents in among these layouts (https://trello.com/u/k3ll3rpl4st8/activity). What is the maximum possible width of a profile? The extrudable profile is computed by determining its industrialized size.

The Facts About Extrusion Of Plastics Revealed

We have actually been doing it right given that 1962 and also are certain that your job will gain from our in-depth experience in:. plastic extrusion manufacturers. https://www.bookmarks2u.com/author/k3ll3rpl4st8/.Flexible forms are commonly coiled onto reels and also shipped to consumers as reel stock. NCS additionally offers co-extruded products of different durometers and also different materials that are co-extruded right into the exact same component. Co-extrusions are used extensively in window and also building applications. If you have questions about co-extrusions or any one of our extruded plastic products, please connect to our team to learn more (https://www.onlinewebmarks.com/author/k3ll3rpl4st8/).

Extruded plastic forms are developed utilizing a high-volume manufacturing process where raw plastic resin material is melted, after that required through a die to form a continual account. To create plastic extruded forms, the resin is positioned into the barrel of an extruder then slowly thawed. Heat and also pressure is after that used to compel the molten plastic into a die.

Getting The Plastic Extrusion Profiles To Work

With simply a small modification, extrusion molding can go from creating intricate shapes to plastic sheets. After plastic leaves the extruder, it stays warm and also can be further controlled. This enables makers to modify the form of extruded plastic using rollers, shoes, or dies to meet the particular demands of many applications.Extruded plastics are used throughout commercial and also commercial applications, with a few of the most common being tubes, rods, as well as specialized profiles. Applications for extruded plastic tubing, rods, and specialty profiles consist of:.

Ask us to address your troubles and also rely upon us for accuracy and on-time delivery.

At Astro Plastics, our period in the industry and also selection of top-end abilities enable us to provide on also the most intricate customer description demand. Our group of experts functions carefully with you to tackle your customized plastic extrusion requires from idea to conclusion, making certain you obtain the appropriate product at the correct time.

Report this wiki page